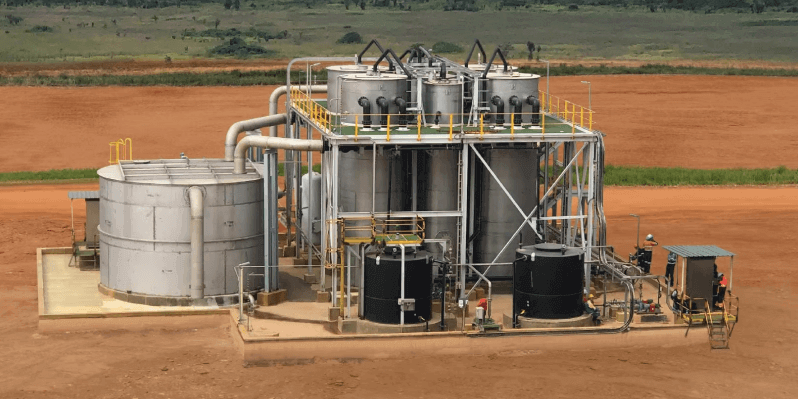

We offer a complete range of solutions for produced water treatment in the oil and gas industry. Our solutions are both high-quality and cost-effective . With our state-of-the-art technology, we are equipped to tackle the most complex produced water treatment challenges, assisting our clients in achieving their environmental and operational objectives .

Over view

OUR SOLUTIONS

DYVAR ® ZLD

Dynamic Vapor Recovery. – Thermal desalination technology with built-for-purpose optimization of recovery vs. energy intensity, with modular design fit for the O&G industry.

Features

- - High Salinity to Freshwater Conversion: Dyvar is designed to convert high-TDS water up to 200k+ ppm into freshwater, making it a leading solution for circular water economy.

- - High Recovery and Low Waste: With 85%+ recovery rate, Dyvar system ensures minimal waste generation while efficiently treating average TDS produced water feed.

- - Optimal Energy Intensity: Dyvar incorporates heat recovery and low heat optimization methods to minimize energy consumption, making it a highly energy-efficient solution.

- - Zero Liquid Discharge (ZLD): Dyvar system produces a concentrated brine reject stream that can be further processed via crystallization, thereby creating a valuable byproduct and achieving zero liquid discharge.

- - Potential Mineral Recovery: ZLD reject stream can also be processed for highly economical mineral recovery, depending on the feed study.

Green DYVAR ®

can be powered by flare gas, heat-to-power, or renewable energy, making it a sustainable and eco-friendly solution for water treatment.

Partners

HIROX ®

A revolutionary two-step process that combines upstream continuous ion filtration (CIF) with high recovery reverse osmosis (RO) to enhance water treatment efficiency. The innovative technology improves the recovery and energy intensity of downstream RO while reducing waste and associated costs.

Learn MoreFeatures

- - Selective heavies removal: Selective removal of specific contaminants such as heavy metals like calcium and magnesium from process water without chemicals.

- - Fouling resistant: With CIF removing scaling agents upstream, the downstream RO membranes are less prone to fouling, which means reducing maintenance and increasing membrane service life.

- - Tunable salt output: The output of the HIROX + CIF system can be adjusted to produce a tenable brine for internal use in the oil and gas industry. The input process water becomes output brine or kill fluid, creating a circular economy.

- - Continuous process: The HIROX + CIF system uses transfer tanks to keep one CIF column in a state of constant regeneration with recycled brine, which enables a continuous process with high efficiency.

- - Optimal recovery vs. energy intensity: Optimal performance in recovery and energy intensity compared to traditional methods and RO.

- - Waste reduction: The HIROX + CIF system's high recovery rate reduces the volume of reject water and waste costs associated with traditional treatment methods.

Partners

Case Study

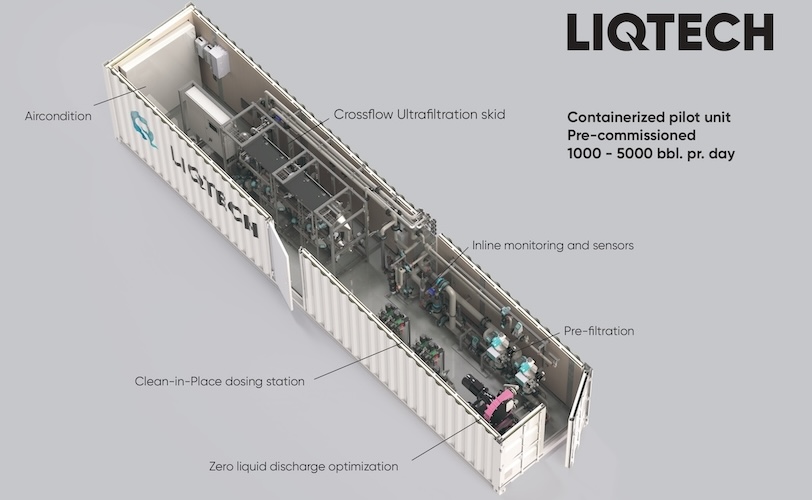

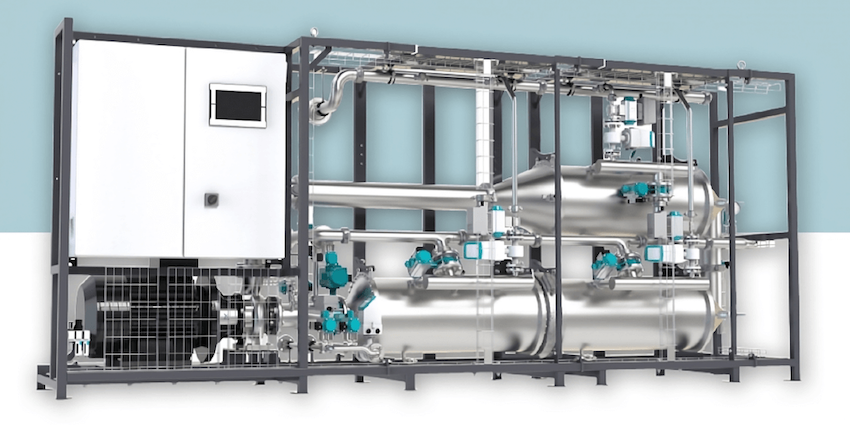

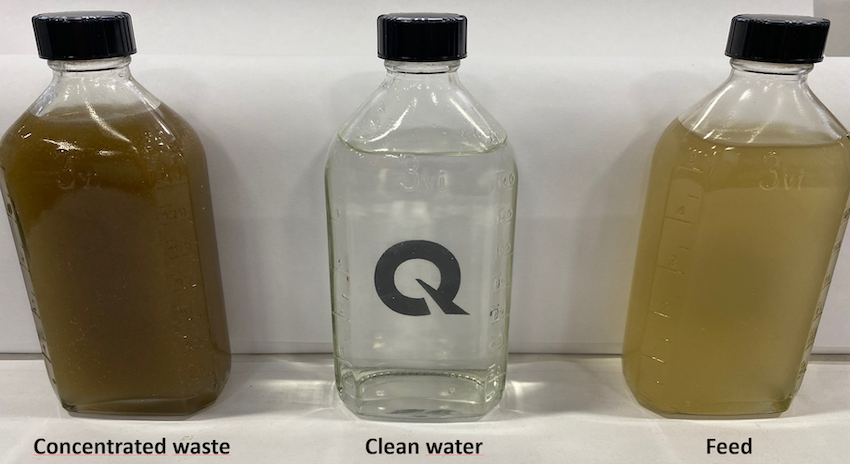

Silicon Carbide (SiC) Membrane

A revolutionary hydrophilic and oilophobic membrane with a negative surface charge that repels oils and provides a solution to a variety of water treatment challenges, polymer flooded PW & heavy Oil.

Features

- - Fit for Oil & Gas: The highest capacity and most robust performance properties of any membrane material, making it ideal for oil and gas applications.

- - Consistent Output: SiC Membrane provides consistent permeate quality despite fluctuations in Total Suspended Solids (TSS), Oil in Water (OiW), and temperature.

- - Less Fouling: SiC Membrane is more stable and has an increased lifetime compared to oxides. It is also abrasion, chemical, and scaling-resistant, and has an optimal weight/footprint/energy ratio.

- - Combined Treatment: SiC Membrane offers secondary and tertiary treatment in a single step.

- - Multiple Applications: SiC Membrane achieves unmatched TSS and OiW removal, complying with tightening environmental regulations and contributing to a water circular economy. It is suitable for various oil and gas applications, including produced water treatment and unconventional/EOR, such as frac flowback, SAGD, and polymer flood PW for sensitive reservoir requirements.

Partners

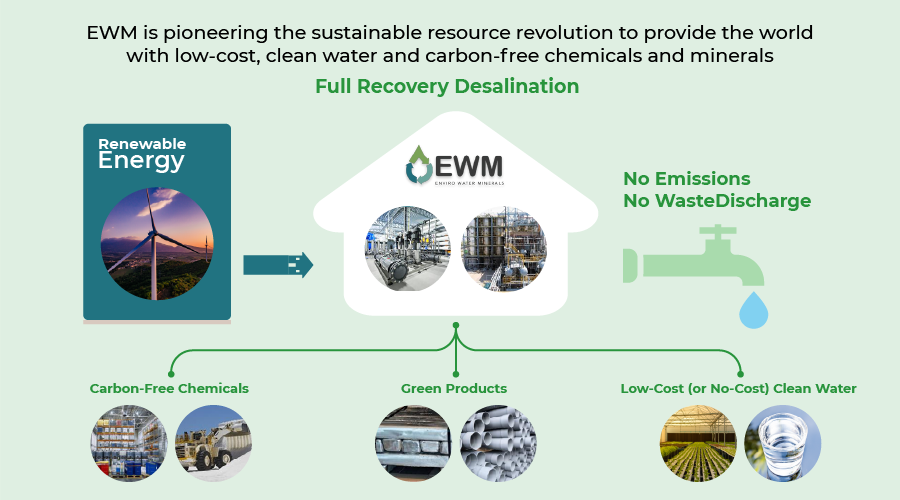

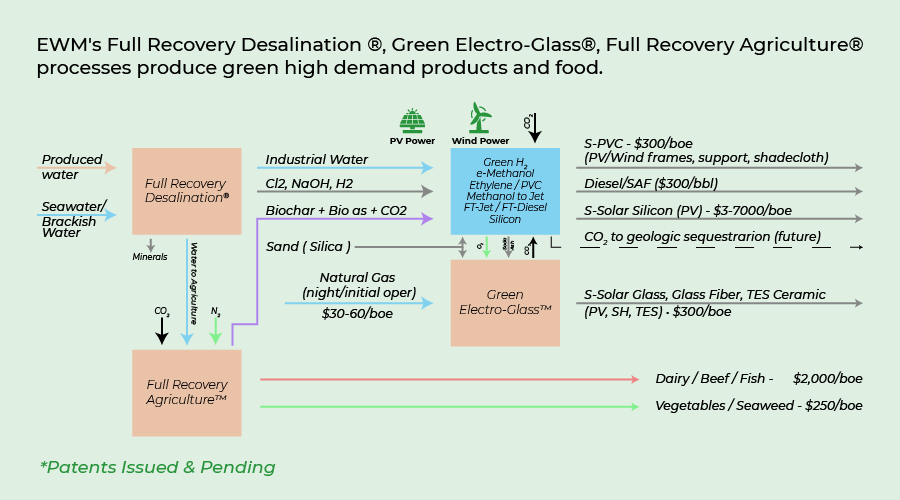

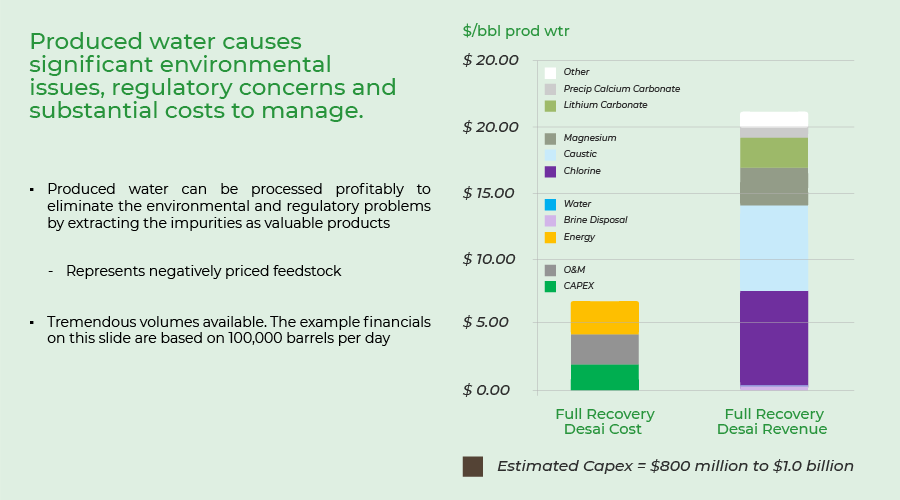

Full Recovery Desalination ®

EWM has created a revolutionary desalination solution that extracts dissolved solids (TDS) from the salt water sources, and maximizes the value of the products in its “Mineral Refinery” concept. EWM prioritizes the salts, minerals, and hydro-chemical products first, and freshwater second, and with a broad collection of 38 US & International patents can deliver a tailored solution for the specific produced water source.

Features

- - Uses tried & true technologies & commercially available processes, in a proprietary flowsheet that maximizes the value of everything found in the water.

- - Zero waste, as all water constituents are used.

- - Generates clean water for many possible uses.

- - Generates byproduct chemicals that can be re-used in O&G operations.

- - Is environmentally sustainable, and eliminates produced water handling & disposal challenges.

Partners