NESR is committed to providing technologies & services that enhance our customers' performance by helping them reduce their environmental impact and lower the carbon intensity of their operations. We are dedicated to maintaining a sustainable and socially responsible company and strive to reduce our environmental footprint everywhere we operate, both internally in our operations and externally in the products & services that we provide.

Climate Change

We recognize the effects of climate change on our planet and our business and align our approach with the United Nations Sustainable Development Goals. We are focused on reducing our environmental footprint and mitigating climate change risks to our business while continuing to help our customers provide the world access to affordable, efficient, and reliable energy. When assessing our risk exposure, we consider risks associated with climate change and their impact on our business in the near and long-term.

Air Emissions

As a service and solutions provider, NESR is well positioned to combat air emissions across the upstream value chain, particularly by bringing new technologies to the region to help detect, quantify, and reduce emissions such as vented and fugitive methane. In 2021,NESR invested in and partnered with a leading Continuous Emissions Monitoring (CEM) platform in North America, Qube Technologies, to deploy next-generation Internet-of-Things (IoT) devices and AI-enabled software for the purpose of CEM internally across NESR operations, and also with our clients.

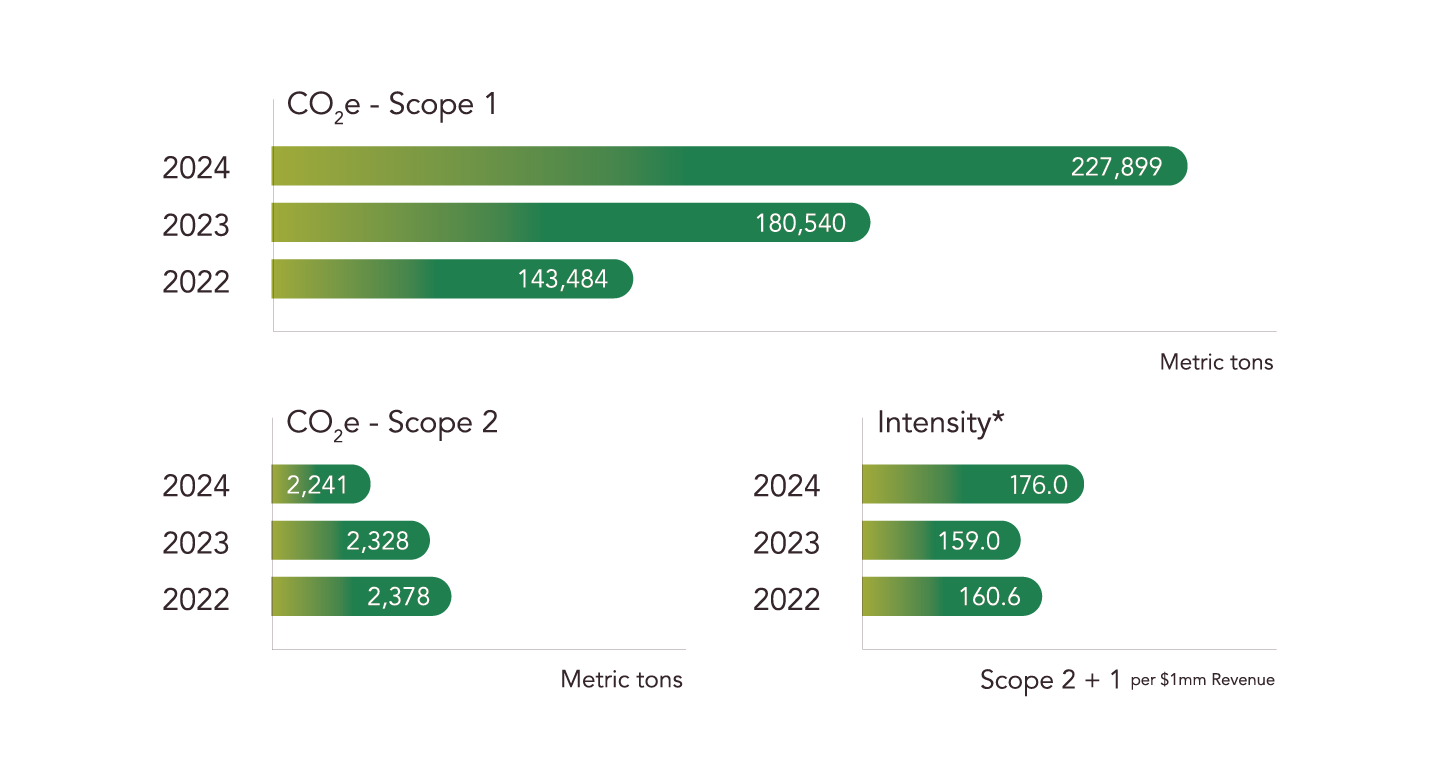

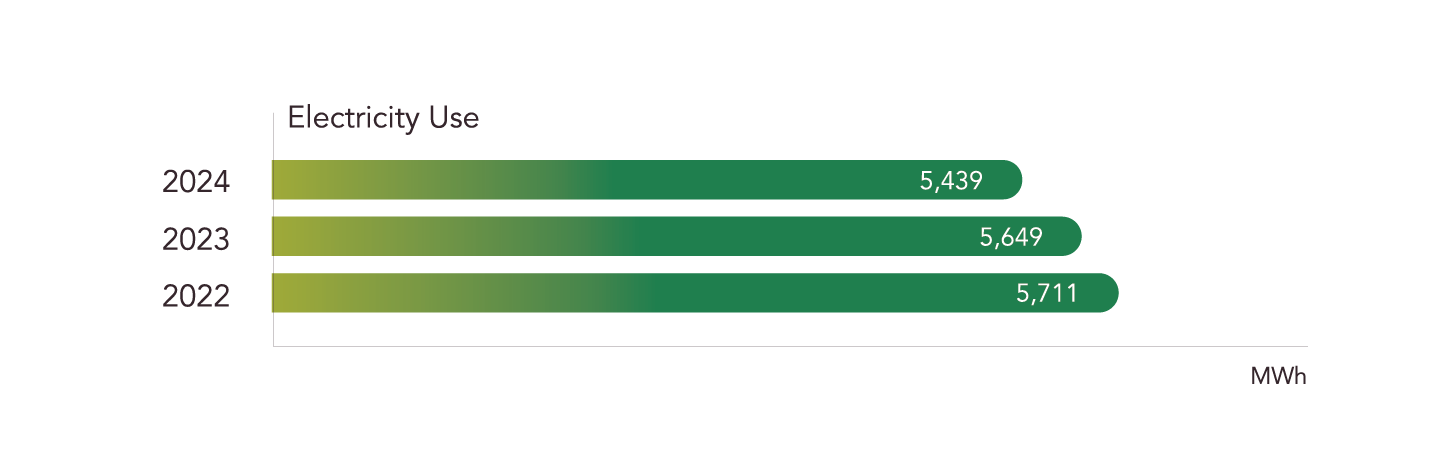

Energy Management

NESR is a fundamental part of an upstream energy industry that currently provides access to affordable, reliable, often sustainable, and modern energy for all, and is an active innovator within our sector to push urgent action to combat climate change and its impacts. We continually improve our practices and invest in facility upgrades by using energy-efficient equipment, implementing current best practices, and increasing our use of alternative and clean energy. Since the establishment of our ESG practice, we’ve tracked our total energy consumption from different sources to improve energy efficiency and increase the percentage of energy we consume from renewable sources.

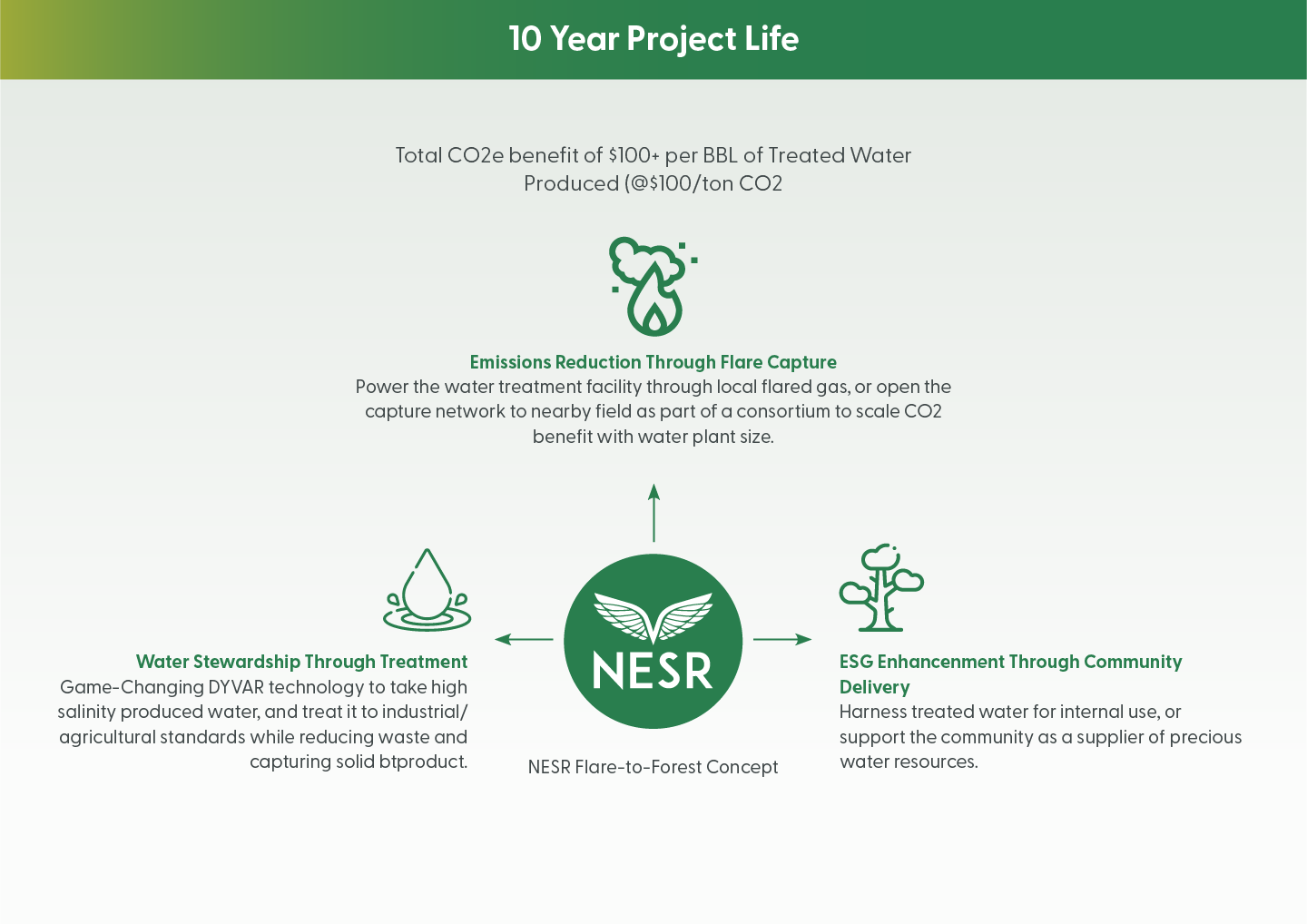

Water Management

Water is one of the world’s most valuable resources and we operate in water-scarce areas in the MENA region. We apply best practices and technological solutions to water management challenges to reduce the impact of our operations on water resources everywhere we operate.

Waste Management

We are committed to reducing the environmental impact of our activities across the entire value chain. We continuously strive to improve our environmental performance in multiple ways, including responsible waste management. To manage waste materials more efficiently, we reuse, when possible, recycle both in our operations and for our customers, and use innovative technologies to find new recovery methods. We continue to seek opportunities to reduce both our direct consumption of resources and the waste we generate. Additionally, NESR audits waste service providers to ensure appropriate waste treatment and disposal practices are followed.

Environmental Releases

Each NESR site is equipped with appropriate emergency control and spill prevention plans. As part of NESR's process safety procedures, barriers are crucial to reducing the risk of uncontrolled release of formation fluids. NESR has a portfolio of cementing technologies and logging tools for ensuring and evaluating well integrity. Zonal isolation is created and maintained in the wellbore through the cementing process. Cement supports and protects well casings and helps prevent fluids in one zone from mixing with fluids in another zone. The cement systems help establish zonal isolation work in a variety of reservoir conditions and remain in place throughout the life of the well.

Chemical Transparency

During the design and development phase of fracturing, all chemical additives are selected based on minimizing environmental impact and regulatory acceptance in the operating companies and countries where we operate. These chemical formulations are also designed to be safe for the individuals who are handling them, from the manufacturing plant to the final oilfield application.

Environmental Compliance

NESR’s operations are conducted in compliance with industry standard certification programs, including those for quality management (ISO 9001), environmental management (ISO 14001), and health and safety management (ISO 45001 or OHSAS 18001). The NESR integrated HSE management system is aligned with ISO 9001/14001/45001.

Environmental Achievements

Our environmental achievements this year are broad ranging.