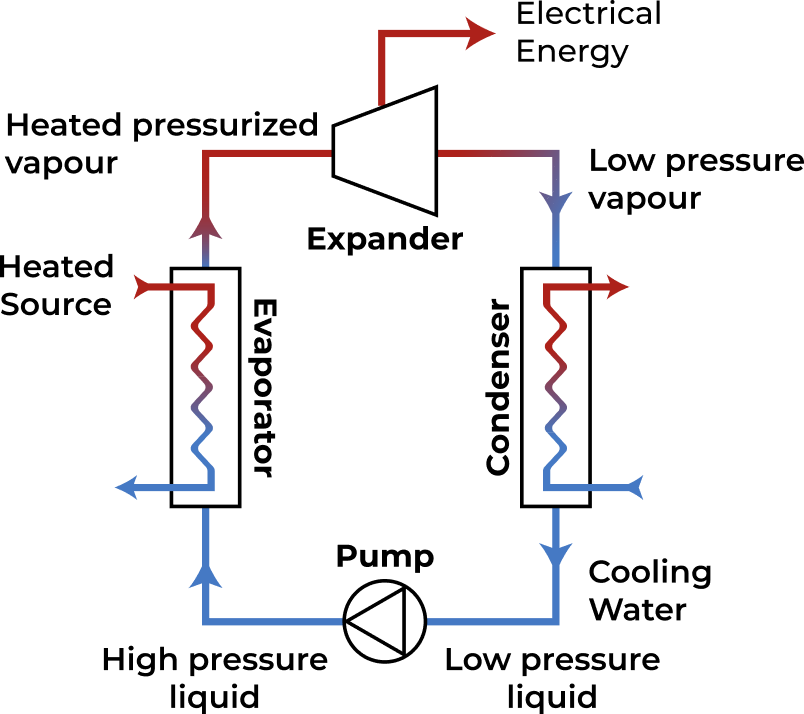

NESR Heat Capture is a unique solution that combines an "ICE Pack" Heat Exchanger with an Organic Rankine Cycle (ORC) Unit to convert harvested heat into emission-free power. The system works by aggregating and modulating a closed-loop COR generator, providing a zero-emissions heat-to-power modular, mobile, and plug-and-play solution. The Organic Rankine Cycle (ORC) machine, unlike traditional Rankine cycle machines, uses organic fluid (such as isobutane, pentane, propane, carbon dioxide, R245fa, etc.) for expansion instead of water vapor, making it more efficient at lower temperatures.

OUR SOLUTIONS

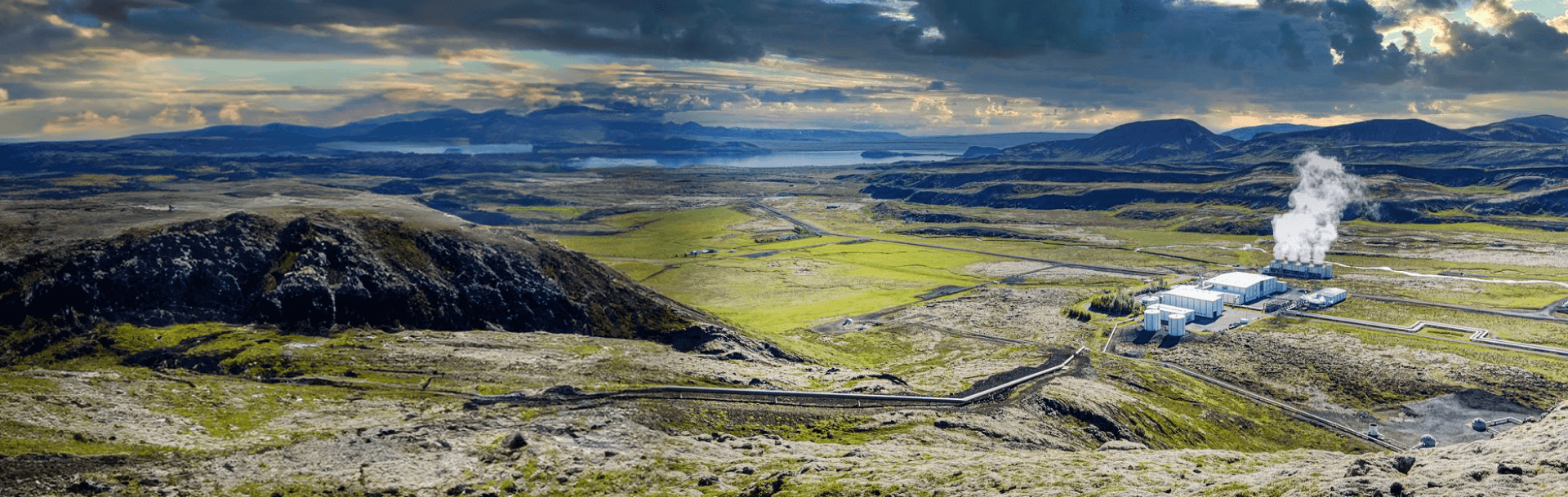

Heat Capture & Geothermal Impact

Features

- - Cost-Effective and Carbon-Negative Power Generation: NESR Heat Capture leverages waste heat to subsidize electricity needs at the source, resulting in cost-effective and carbon-negative power production.

- - Process Stream Flexibility: This solution is agnostic to the type of heat carrying fluid, whether it is liquid, vapor, or mixed-phase.

- - No EPC Required: it is easy to deploy without major civil infrastructure, eliminating the need for major construction projects.

- - Bevy of Applications Across the Value Chain: NESR Heat Capture can capture heat beyond the wellhead, including access to geothermal energy from producing O&G wells, midstream processing and compression waste heat, downstream/refining and LNG processing heat, and reducing or eliminating the cooling duty of various processes.

- - Tailored Process Control (PLC): NESR Heat Capture's process control system is designed to govern thermal flow into the ORC based on asset parameters during initial design, ensuring efficient operation from the outset.

- - Continuous Tuning: Ongoing equipment and process tuning is based on data feedback and response to changing conditions, ensuring that the system operates at maximum efficiency over time

- - Cutting-Edge Working Fluid Chemistry: leverages the latest advancements in organic Rankine loop fluid to optimize system performance.

- - Parallel Lab Testing: NESR's R&D facility (NORI - Saudi Dharan Techno Valley) is used for parallel lab testing, enabling project optimization and continuous improvement.

Working of ORC Unit

Partners